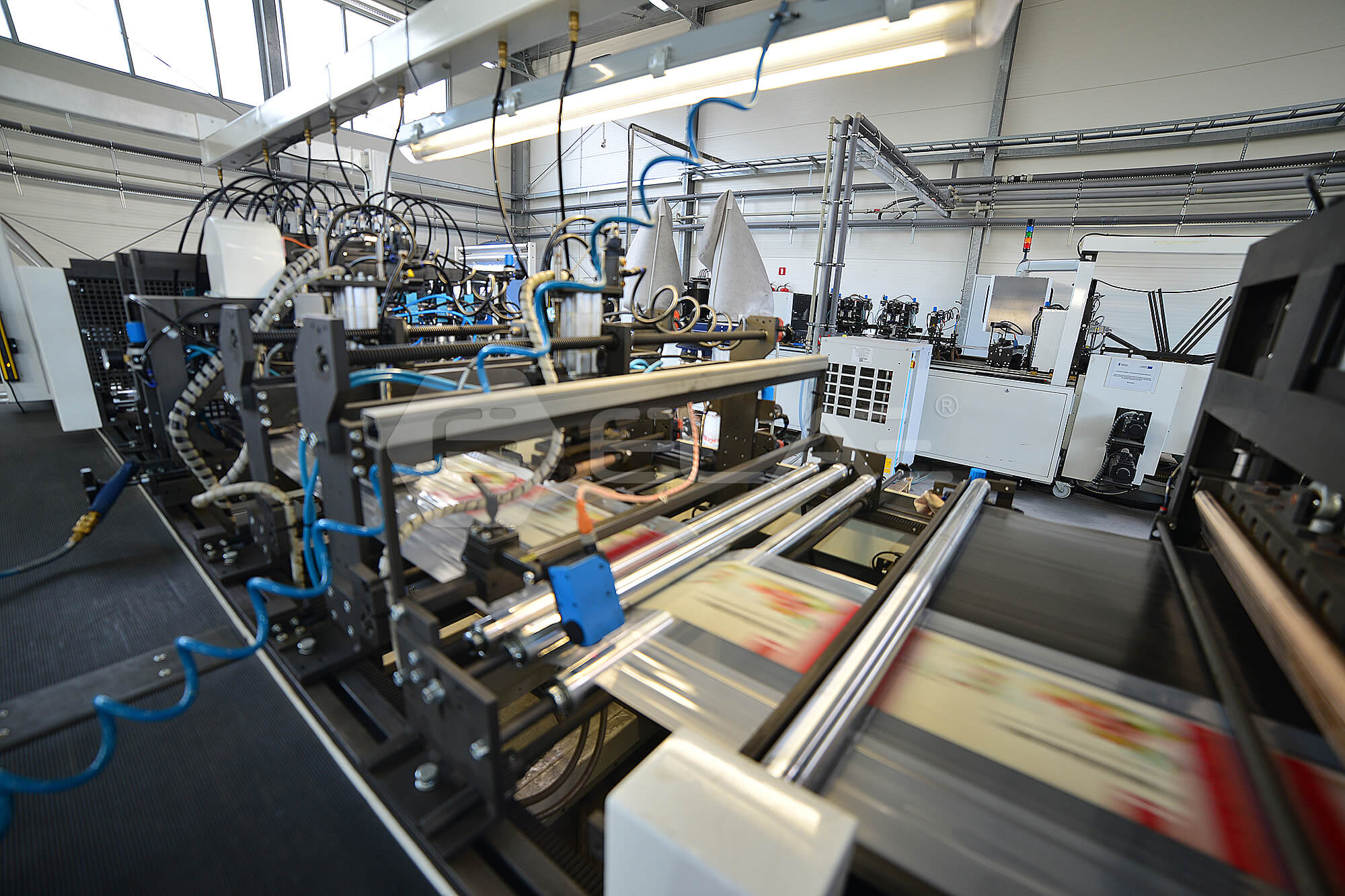

The confection department consists of three reel cutting machines that allow cutting the film produced by extrusion blow molding to a specific length and width, depending on the customer’s requirements. Each of the devices is additionally equipped with perforators, respectively: a hot perforator (rice bags, porridge), two laser perforators allowing the burining of holes in the substrate in size from several to several dozen microns with specified repeatability (microperforation) and perforators allowing to cut holes with a diameter of 6, 8, 10, 12 or 14 mm (macroperforation).

CONFECTION

CONFECTION

The confection department also includes three sealing machines. Two of them are used for the production of bags on the roll (polyethylene bags with a handle for apples, or simple ones for carrots) of various sizes with possible macroperforation. The third machine, however, allows the production of wicket and simple bags, used in various industries.